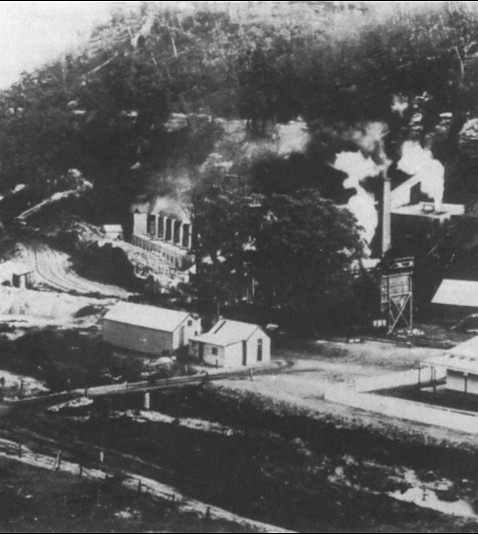

[click on image to enlarge]

History

Oakey Park Colliery operated from 1888 to 1941. It was one of only two Western coalmines to manufacture coke, the other being the Vale Colliery where coke was manufactured very briefly from 1892 until 1900.

The sinking of a circular shift lift in diameter was begun by the Oakey Park Coalmining Company in 1887 using three shifts of sinders working 24 hours per day. By 1888, the surface works had been completed and the winding shaft had reached 327 ft to the bottom of the Lithgow Valley coal seam. The winding engine had two coupled cylinders of 11in x 3ft. In 1889, an air shaft 8ft in diameter was sunk. Its final depth was 340ft. In 1899, sixteen beehive coke ovens were erected at the colliery and during 1900, a further sixteen were built, giving a collective capacity of 132 tonnes of coke per week. Initially, the entire output was sold to the Blayney copper smelting works. By 1906, forty new rectangular ovens had been built in order to fulfill an extensive contract with the Sandford iron-smelting furnace at Lithgow. At the time, these coke ovens were the largest in the State, each being 8ft x 30ft, with a total capacity 400 tonnes of coke per week. Charging was from overhead canister trucks, discharging by travelling steam ram, with the doors being hoisted by hydraulic lifts.

When the ironworks were taken over the C. & G. Hoskins in 1908, Oakey Park Colliery continued to supply the coke for the blast furnace. With the erection of a second blast furnace by Hoskins in 1913, the demand for coke far exceeded the output of Oakey Park. Hoskins consumed all the coke produced at Oakey Park and augmented it with coke purchased from the South Coast. Later Hoskins purchased their own collieries and erected their own coke ovens at Eskbank and on the South Coast.

Ventilation of the underground workings at Oakey Park was by furnace with side flues and exhaust steam from the pumping engine. It increased over the years between 15,000 and 18,000 cu. ft. of air/min. to cater for between 28 and 51 men underground, plus horses. By 1903, 90 men were winning coal by contract. By 1923, 175 men were employed underground, ventilation was being supplied by a 70 inch diameter Sirocco fan at 60,000 cu. ft./min. The coal face was two miles from the shaft, haulage was by endless rope, and output was 500 tonnes/day. Both team and electric pumps were used for draining the mine. Both shafts had winders with cages and the men used the upcast shaft to allow more time for winding coal from the down-cast station. It generated and supplied limited amounts of electricity to Lithgow Council and Blaxland Shire Council.

[click on image to enlarge]

Poppet Head 6

Clearly dominates the site. In effect two, structures with the outer structure made of long lengths of ironbark beams supporting a platform into which the two winding wheels are set. Ironbark beams and lengths of steel piping brace the Poppet Head internally. Features to metal winding wheels.

Within this Poppet Head lies another timber structure associated with the up cast shaft. Four vertical poles rest against a metal block. The whole is braced internally by timber beams and it stands independent by of the Poppet Head. The four poles mark the margin of the downcast shaft. This structure was presumably for winching the skip cars.

Winding Room 1 and pier buttresses 7

The pier buttresses are of two types – differences being in size and materials used in construction.

The first type is generally made of mortared brick. Three piers of this type are relative to the poppet head support props.

The second type is a mixture of roughly dressed sandstone blocks and bricks mortared together. These are generally lower and shorter than Type One and are not associated with the Poppet Head. They have been interpreted as engine mountings for the first winding engine which was associated with sinking the shaft and the initial years of operation. This is mirrored in the case of Winding Room 2.

The Winding: Room is a brick structure which may be assumed to have originally been roofed with corrugated iron over timer rafters. It is built into the hillside and this location has determined its design – basically a brick shell with two large brick engine mountings present in the centre and directly in line with the large aperture in its facade.

Remains of coal loading bins 9

The coal loaders were presumably erected after 1908. Associated with the railway line which ran adjacent to their southern margin, coal not intended for the coke ovens would be loaded onto railway trucks passing beneath them..

The four concrete pillars remaining are found on the margin of the cleared and raised area which contained the Boiler House (10), Power House (8), Shaft No. 2 (11) and the Fan Room (13). Little survives apart from a length of timber spar over two of the pillars.

Remains of Powerhouse 8

All that remains is a concrete raft with a circular depression in the centre. This is said to have housed a steam-driven engine. Original fabric and design of the structure is not known, as no pit-top plans survive. However in view of the fabric which dominates the rest of the site either brick with corrugated iron roofing or a complete corrugated iron structure are the likely options. The same applies to the Boilerhouse (10). Of interest are the small brick supports that run alongside the Powerhouse, Boilerhouse and Winding Rooms 1 and 2. These are interpreted as being supports for piped live steam – generated in the Boilerhouse and used to run all steam engines on the site. No piping remains, but the supports are in a reasonable shape of preservation, both individually and as a group indicating direction and extent of the piped steam.